Advancements in Haptic Feedback Surfaces for Robotic Applications

The integration of advanced haptic feedback surfaces into robotic systems represents one of the most significant breakthroughs in human-robot interaction. These innovative surfaces allow robots to perceive and respond to touch in ways that closely mimic human sensory capabilities.

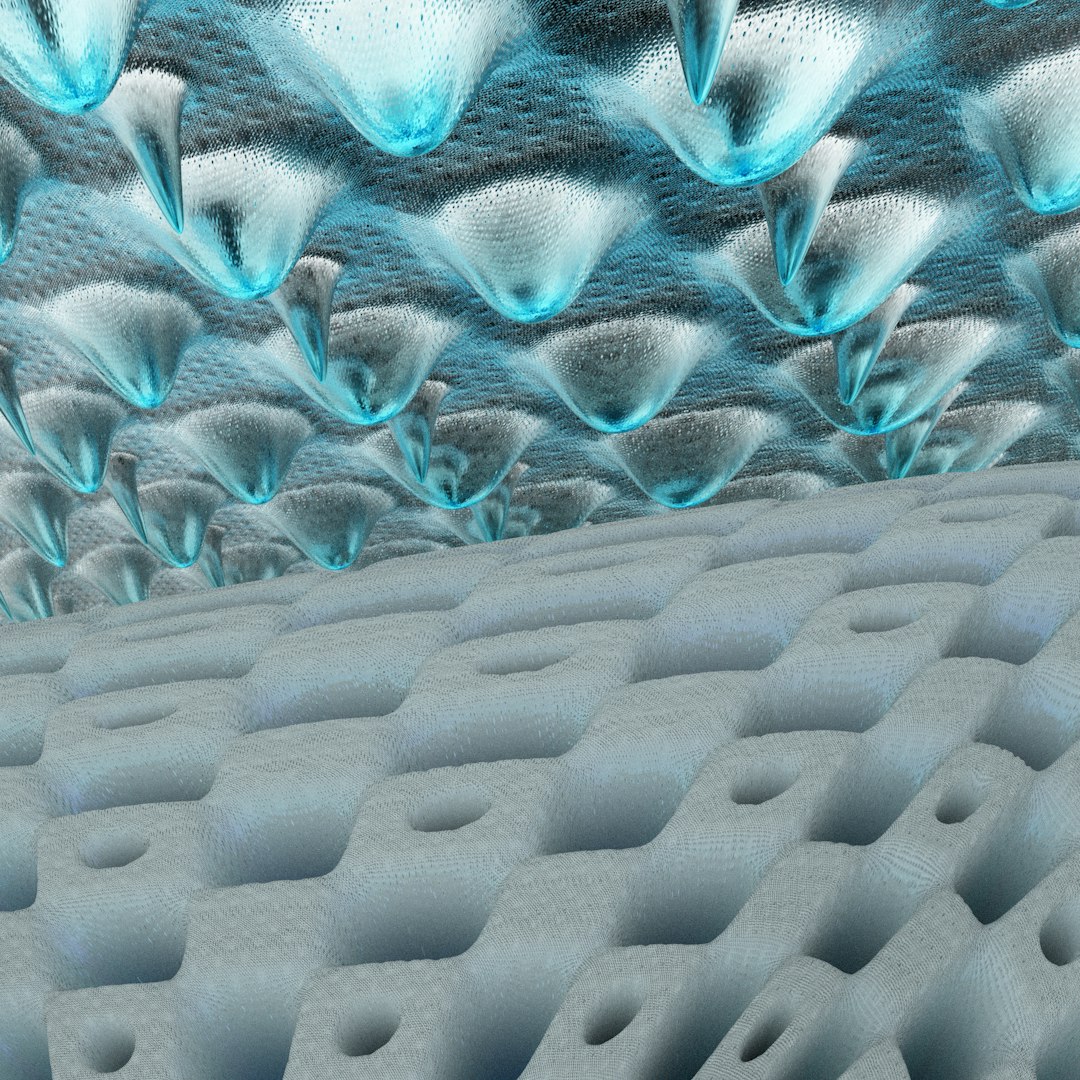

Recent developments in electroactive polymers have enabled a new generation of artificial skin that can detect multiple pressure points simultaneously, providing robots with unprecedented tactile awareness. These materials change their electrical properties when mechanical force is applied, allowing for precise measurement of pressure distribution across a surface.

Applications for these haptic surfaces extend beyond industrial robotics into healthcare, where surgical robots equipped with sensitive touch feedback can assist surgeons in performing delicate procedures. The ability to "feel" tissue resistance during robot-assisted surgery provides vital information that was previously unavailable in minimally invasive procedures.

Challenges remain in scaling these technologies for larger robotic applications while maintaining sensitivity and response time. Researchers are currently exploring nanostructured composites that may offer improved durability without sacrificing the delicate sensing capabilities required for complex interactions.

As we continue to refine these haptic systems, we can expect to see robots that interact with their environment in increasingly intuitive ways, opening new possibilities for collaborative robotics in manufacturing, healthcare, and daily assistance tasks.